- DTE Code : 6446

- MSBTE Code : 0993

- AICTE PID : 1-407330281

Mr. Shashikant Phulari

HOD- Mechanical Engineering

M.E. ( Mechanical Design)

shashiphulari25@gmail.com

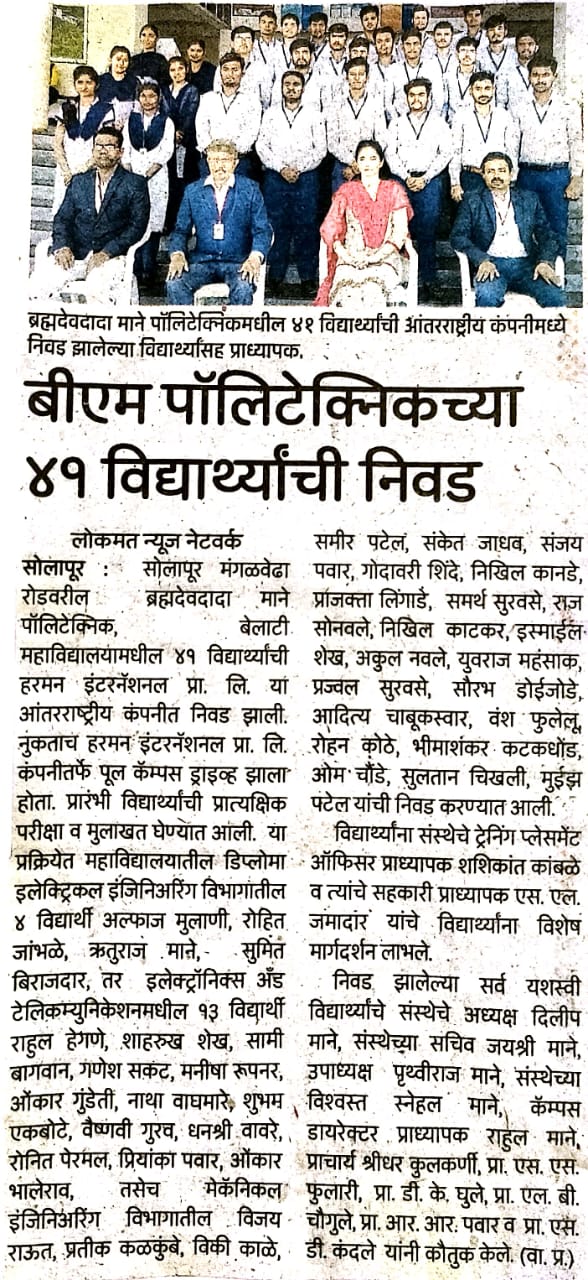

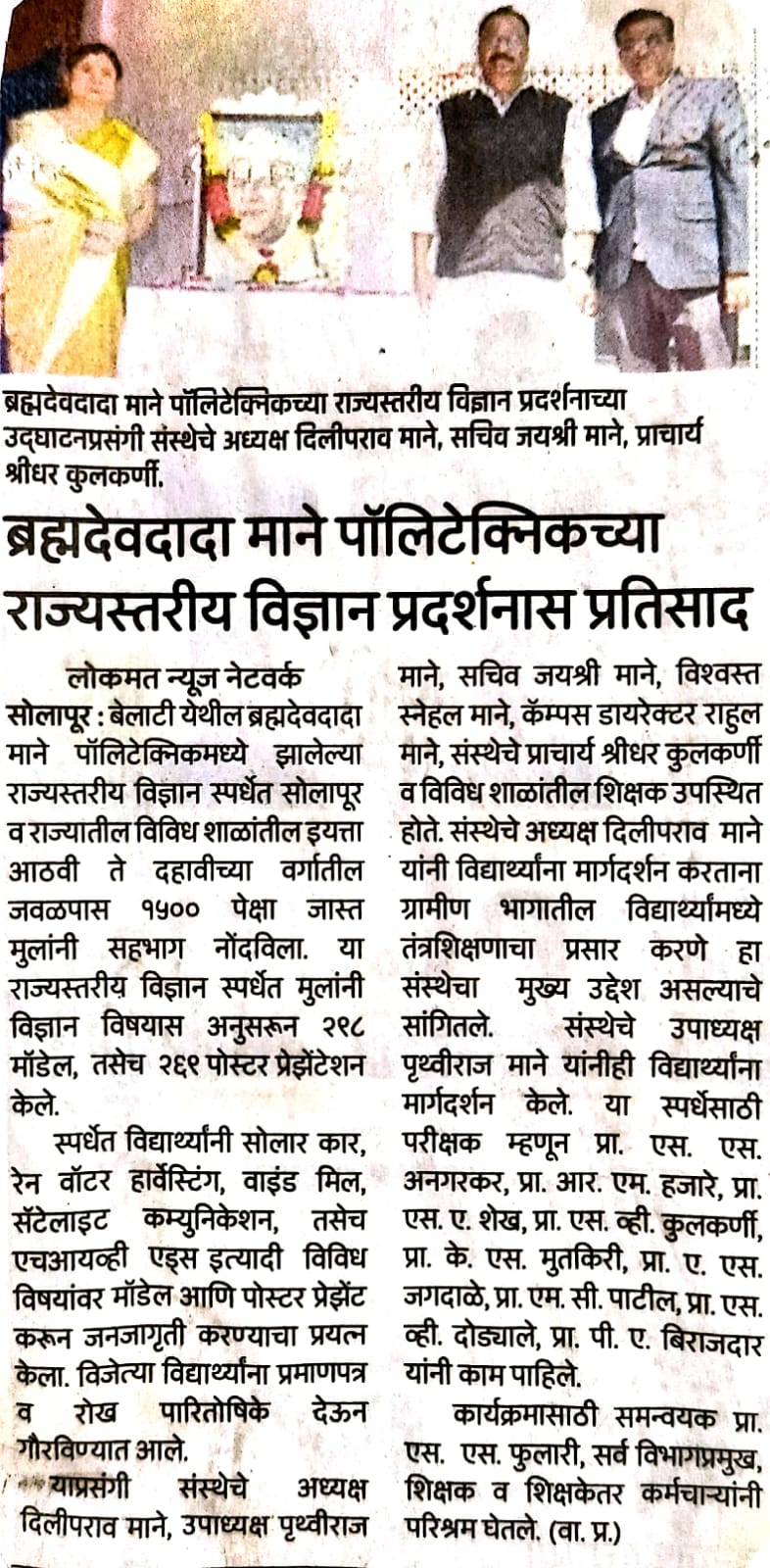

The Department of Mechanical Engineering at Brahmdevdada Mane Polytechnic is one of the best departments in Solapur. Starting in 2008, we persistently seek and adopt innovative techniques to improve the quality of education and strongly believe in outcome-based education philosophy. We are affiliated with the prestigious M.S.B.T.E Mumbai University with an intake of 60 seats at the undergraduate level. We believe in creating value for our stakeholders. In addition to enriched academics, we impart industry-demanded skills from time to time.

The skill development program in our department is one of the most unique activities. Through this program, we impart the latest skills that are needed in the industry. Technical, professional, social, and interpersonal aspects of student personality are some of the key attributes that are honored at our department. Excellent curricular, co-curricular, extra-curricular, and extension activities are our performance indicators. The journey of student learning from fundamentals to advances in mechanical engineering at our department is accompanied by several value-added activities.

Department of Mechanical Engineering is established in 2008 with intake of 60 students.

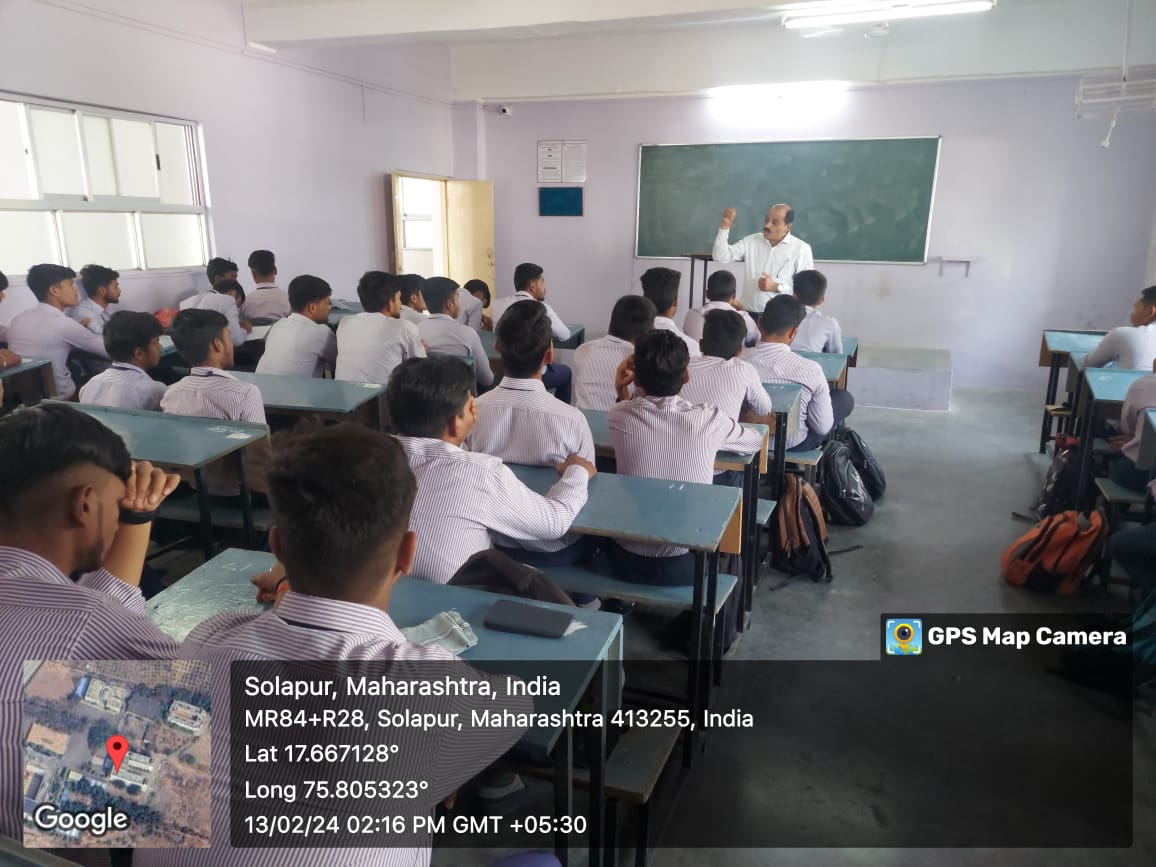

The department is enriched with highly qualified and well experienced faculties ready to take challenges of mentoring the future Diploma Engineers, who are fit to take any challenges in the field. Besides academic, department motivates the students for overall development.

Department promotes faculty for higher education. Departmentdepute faculties to attend faculty development training program to upgrade technical knowledge.

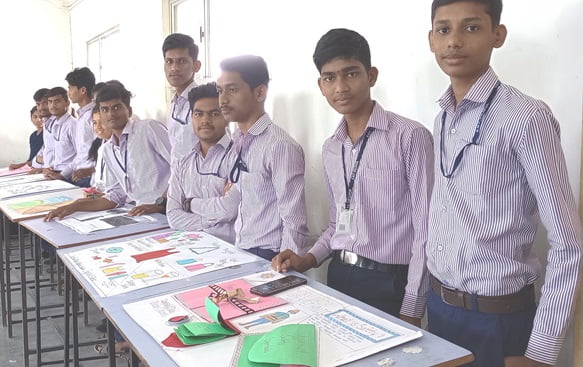

Regular industrial visits, industrial training, workshops, interaction with field experts along with participation in various cocurricular events is facilitated by the staff of the department in the interest of students for the better grooming and overall development of the students.

Department has well equipped laboratories wise Computer Aided Drafting, Metrology and Quality Control, Mechanical Engineering Materials, Thermal & Power Engineering, Refrigeration & Air Conditioning, Fluid Mechanics & Fluid Power, Theory of Machine, Drawing Hall. All laboratories are supported with charts/models for additional information to students.

The department is awarded with “Excellent” grade by External Academic Monitoring, MSBTE, Mumbai.

Department provides training and placement assistance to all students.

| Sr. No. | Name | Qualification | Designation | Date of Joining | Experience | Nature of Work | Research Interest | Photo |

|---|---|---|---|---|---|---|---|---|

| 1. | Phulari Shashikant Shivputra | M.E. (Design) | HOD | 01-11-2008 | 25 Years | R | Mechanical Design Engineering |

|

| 2. | Patil Dhareshwar Subhash | M.E. (Design) | Selection Grade Lecturer | 01-04-2022 | 14 Years | R | Mechanical Design Engineering |  |

| 3. | Lamkane Anup Abasaheb | M.E. (Design) | Sr. Lecturer | 03-06-2013 | 11 Years | R | Mechanical Design Engineering |  |

| 4. | Gaikwad Rushikesh Babasaheb | M.E. (Design) | Sr. Lecturer | 01-04-2022 | 11 Years | R | Mechanical Design Engineering |  |

| 5. | Jamadar Saiphan Liyakat | M.Tech (Thermal) | Selection Grade Lecturer | 13-07-2018 | 12 Years | R | Thermal Engineering |  |

| 6. | Soma Sudhir Pandurang | B. E. | Sr. Lecturer | 03-07-2019 | 14 Years | R | Mechanical Engineering |  |

| 7. | Randive Sonali Achyut | M.E. (Design) | Lecturer | 01-04-2022 | 05 Years | R | Mechanical Design Engineering |  |

| 8. | Neel Laxman Mahavir | B.E | Lecturer | 20/08/2024 | 6 Years | R | Mechanical Engineering |  |

Non Teaching Staff

| S. N. | Name of Staff | Total Experience | Designation | Email Id | Photo |

|---|---|---|---|---|---|

| 1 | Pawan Dharmaraj Ghodake | 5 | Technical Lab Assistance | ghulean12@gmail.com |  |

| 2 | Rahul Namdev Yadav | 5 | Technical Lab Assistance | fulari.sachin@gmail.com |  |

| 3 | Dattatray Machindranath Kadam | 5 | Technical Lab Assistance | fulari.sachin@gmail.com |  |

| 3 | Rachayya Gurupadayya Hiremath | 5 | Technical Lab Assistance | rachayyahiremath688@gmail.com |  |

| 3 | Amol dattatray Jadhav | 5 | Technical Lab Assistance | amoljadhav8855@gmail.com |  |

Vision:

“To be identified as an excellent destination for Mechanical Engineering studies responsive to industrial and social needs.”

Mission:

- To prepare the students for placement and higher education by providing a conducive environment and infrastructural facilities.

- To achieve academic excellence in the mechanical engineering field by providing high-quality training.

- To impart high ethical and moral values and develop socially responsible engineers.

PEO1. Provide socially responsible, environment-friendly solutions to Mechanical engineering-related broad-based problems adapting professional ethics.

PEO 2. Adapt state-of-the-art Mechanical engineering broad-based technologies to work in multidisciplinary work environments.

PEO 3. Solve broad-based problems individually and as a team member communicating effectively in the world of work.

PSO1 : Modern Software Usage :

Use latest Mechanical engineering related software for simple design, drafting, manufacturing, maintenance and documentation of Mechanical engineering components and processes

PSO2 : Equipment and Instruments :

Maintain equipment and instruments related to Mechanical Engineering

- PSO3 : Mechanical Engineering Processes :

Manage Mechanical engineering processes by selecting and scheduling relevant equipment, substrates, quality control techniques, and operational parameters

- PO1: Basic and Discipline-specific knowledge:

Apply basic mathematics, science, and engineering fundamentals knowledge and an engineering specialization to solve engineering problems.

- PO2: Problem analysis:

Identify and analyze well-defined engineering problems using codified standard methods.

- PO3: Design/ development of solutions:

Design solutions for well-defined technical problems and assist with designing systems components or processes to meet specified needs.

- PO4: Engineering Tools, Experimentation and Testing:

Apply modern engineering tools and appropriate techniques to conduct standard tests and measurements.

- PO5: Engineering practices for society, sustainability, and environment:

Apply appropriate technology in the context of society, sustainability, environment, and ethical practices.

- PO6: Project Management:

Use engineering management principles individually, as a team member, or as a leader to manage projects and effectively communicate about well-defined engineering activities.

- PO7: Lifelong learning:

Ability to analyze individual needs and update in the context of technological changes.

Classroom Details are given below in table

| Sr. No | Infrastructure | Quantity |

|---|---|---|

| 1 | Class Room | 03 |

| 2 | Tutorial Room | 01 |

| 3 | Drawing Hall | 01 |

| 4 | Seminar Hall | 01 |

Lab Information

| Sr. No | Name of The Laboratory | Major Equipment | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | Fluid Power & Fluid Mechanics Lab |

| |||||||

| 2 | Power Engineering Lab |

| |||||||

| 3 | Thermal, Refrigeration & Air Conditioning Lab |

| |||||||

| 4 | CNC MACHINES Lab |

| |||||||

| 5 | Metrology & Quality Control Lab |

| |||||||

| 6 | Auto Cad Lab |

| |||||||

| 7 | Theory of machine lab |

| |||||||

| 8 | Mechanical engineering measurement lab |

| |||||||

| 9 | Workshop |

|

- Software:

- Auto Cad 2011

| MECHANICAL ENGINEERING PROGRAM |

|---|

| SEMESTER - FIRST | |

|---|---|

| Co No. | Course Outcomes |

| Course Name: ENG 22101 | |

| C101.1 | Formulate a Grammatically Correct Sentence |

| C101.2 | Summarize the Comprehension Passage |

| C101.3 | Compose dialogues and paragraphs for different situations |

| C101.4 | Use relevant words according to the content. |

| C101.5 | Deliver prepared speeches to express ideas, thoughts, and emotions. |

| Course Name: BSC 22102 | |

|---|---|

| C102.1 | Estimate error in measurement of physical quantities |

| C102.2 | Apply the principle of electricity & magnetism to solve Engg. Problems |

| C102.3 | Use the basic principle of heat & optics about Engg. Application |

| C102.4 | Apply the catalysis process in industries |

| C102.5 | Use corrosion preventive measures in the industry |

| C102.6 | Use relevant Engg. Materials in industry |

| Course Name: BMS 22103 | |

|---|---|

| C103.1 | Apply the concept of algebra to solve engineering-related problems |

| C103.2 | Utilize the basic concept of trigonometry to solve elements engineering problem |

| C103.3 | Solve the basic engineering problems under given conditions of straight lines. |

| C103.4 | Solve the problems based on the measurement of regular closed figures and regular solids |

| C103.5 | Use basic concepts of statistics to solve engineering-related problems |

| Course Name: ICT 22001 | |

|---|---|

| C104.1 | Use the computer system and its peripherals. |

| C104.2 | Prepare business documents using a word processing tool. |

| C104.3 | Interpret data and represent it graphically using a spreadsheet. |

| C104.4 | Prepare professional presentations. |

| C104.5 | Use different types of web browsers. |

| Course Name: EGM 22002 | |

|---|---|

| C105.1 | Draw regular geometrical figures |

| C105.2 | Draw the views of a given object using principles of orthographic projection |

| C105.3 | Draw isometric views of a given component or from orthographic projections |

| C105.4 | Use drawing codes, conventions, and symbols as per IS SP-46 in engineering drawing |

| C105.5 | Draw free-hand sketches of given engineering elements |

| Course Name: WPM 22004 | |

|---|---|

| C106.1 | Select tools and machinery according to the job |

| C106.2 | Use hand tools in different shops to perform different operations |

| C106.3 | Operate equipment and machines in various shops |

| C106.4 | Prepare composite/utility jobs according to the drawing. |

| C106.5 | Maintain workshop related tools, instruments, and machines |

| MECHANICAL ENGINEERING PROGRAM |

|---|

| SEMESTER - SECOND | |

|---|---|

| CO No. | Course Outcomes |

| Course Name: ASM 22202 | |

| C201.1 | Select relevant material in the industry by analyzing its physical properties |

| C201.2 | Apply Laws of motion in various application |

| C201.3 | Use LASERs, X- Rays and photoelectric sensors |

| C201.4 | Select the relevant metallurgical process related to industrial applications |

| C201.5 | Use relevant water treatment processes to solve industrial problems |

| C201.6 | Use relevant fuel in the relevant application |

| Course Name: AME 22203 | |

|---|---|

| C202.1 | Identify the force systems for given conditions by applying the basics of mechanics. |

| C202.2 | Select the relevant simple lifting machine (s) for the given purposes. |

| C202.3 | Determine the unknown force (s) of different engineering systems. |

| C202.4 | Check the stability of various force systems. |

| C202.5 | Apply the principles of friction in various conditions for useful purposes. |

| C202.6 | Find the centroid and center of gravity of various components of engineering systems. |

| Course Name: AMP 22206 | |

|---|---|

| C203.1 | Calculate the equation of tangent, maxima, minima, and radius of curvature by differentiation. |

| C203.2 | Solve the given problems of integration using suitable methods. |

| C203.3 | Apply the concept of integration to find area and volume. |

| C203.4 | Solve the differential equations of the first order and first-degree using suitable methods. |

| C203.5 | Use basic concepts of probability distribution to solve elementary engineering problems |

| Course Name: EDR 22207 | |

|---|---|

| C204.1 | Draw projections of 2d,3d standard regular entities |

| C204.2 | Draw a sectional view of the object |

| C204.3 | Draw orthographic sectional and missing view |

| C204.4 | Draw an auxiliary view of the object |

| C204.5 | Use various, drawing codes, conventions, and symbols |

| C204.6 | Draw freehand sketches of given engg element |

| Course Name: BCC 22009 | |

|---|---|

| C205.1 | Communicate effectively by avoiding barriers in various formal and informal situations. |

| C205.2 | Communicate skilfully using non-verbal methods of communication |

| C205.3 | Give presentations by using audio-visual aids |

| C205.4 | Write reports using the correct guidelines |

| C205.5 | Compose e-mail and formal business letters |

| Course Name: MEW 22010 | |

|---|---|

| C206.1 | Select tools and machinery according to the job |

| C206.2 | Use hand tools in different shops to perform different operations |

| C206.3 | Operate equipment and machines in various shops |

| C206.4 | Prepare composite/utility jobs according to the drawing. |

| C206.5 | Maintain workshop related tools, instruments, and machines |

| MECHANICAL ENGINEERING PROGRAM |

|---|

| SEMESTER - THIRD | |

|---|---|

| CO No. | Course Outcomes |

| Course Name: SOM 22306 | |

| C301.1 | Compute the Moment of Inertia of symmetric and asymmetric structural sections. |

| C301.2 | Estimate simple stresses in machine components. |

| C301.3 | Perform tests to evaluate mechanical properties according to India Standards. |

| C301.4 | Compute shear force, bending moment, and corresponding shear and bending stresses in beams subjected to point and uniformly distributed load. |

| C301.5 | Estimate stresses in shafts under twisting moments. |

| C301.6 | Estimate stresses in short members subjected to eccentric loading |

| Course Name: BEE 22310 | |

|---|---|

| C302.1 | Use the principle of Electric and Magnetic circuits to solve engineering problems |

| C302.2 | Determine voltage and current in A.C. Circuits. |

| C302.3 | Connect transformer and DC motors for specific requirements |

| C302.4 | Identify electronic components in an electric circuit |

| C302.5 | Use relevant electronic components safely |

| C302.6 | Use relevant electric/ electronic protective devices safely |

| Course Name: TEN 22337 | |

|---|---|

| C303.1 | Apply laws of thermodynamics to devices based on thermodynamics. |

| C303.2 | Use the first law of thermodynamics for an ideal gas in closed systems. |

| C303.3 | Use relevant steam boilers. |

| C303.4 | Use relevant steam nozzles and turbines. |

| C303.5 | Use relevant steam condensers. |

| C303.6 | Use suitable modes of heat transfer. |

| Course Name: MWM 22341 | |

|---|---|

| C304.1 | Draw the development of the lateral surface of various solids. |

| C304.2 | Draw intersection curves of different solids. |

| C304.3 | Use various drawing codes, conventions, and symbols as per IS SP-46. |

| C304.4 | Draw production drawings used to produce products. |

| C304.5 | Draw assembly and detailed drawings of products. |

| Course Name: EME 22342 | |

|---|---|

| C305.1 | Select the relevant instrument for measurement. |

| C305.2 | Use different types of comparators. |

| C305.3 | Select gauges, fits, and tolerances for machine components. |

| C305.4 | Use relevant instruments to measure different parameters of screw thread and gear. |

| C305.5 | Use linear and angular measuring instruments. |

| C305.6 | Select relevant surface testing methods. |

| Course Name: MEM 22343 | |

|---|---|

| C306.1 | Identify properties of materials. |

| C306.2 | Select relevant ferrous materials for mechanical components. |

| C306.3 | Select relevant cast iron for the engineering application. |

| C306.4 | Use non-ferrous materials for mechanical components. |

| C306.5 | Suggest relevant advanced materials for mechanical components. |

| C306.6 | Select the relevant heat treatment process. |

| MECHANICAL ENGINEERING PROGRAM |

|---|

| SEMESTER - FOURTH | |

|---|---|

| CO No. | Course Outcomes |

| Course Name: TOM 22438 | |

| C401.1 | Identify various links in popular mechanisms. |

| C401.2 | Select suitable mechanisms for various applications. |

| C401.3 | Interpret the motion of cams and followers. |

| C401.4 | Recommend relevant belts, chains, and drives for different applications. |

| C401.5 | Choose relevant brakes and clutches for various applications. |

| C401.6 | Select a suitable flywheel and governor for various applications. |

| Course Name: MEM 22443 | |

|---|---|

| C402.1 | Use relevant instruments for measuring displacement |

| C402.2 | Use relevant instruments for measuring force and torque. |

| C402.3 | Use relevant pressure and temperature measuring instruments |

| C402.4 | Use relevant instruments for measurement of flow. |

| C402.5 | Select relevant instruments for the measurement of vibration and strain. |

| C402.6 | Select relevant instruments for spaced anal sound measurement. |

| Course Name: FMM 22445 | |

|---|---|

| C403.1 | CO1. Use Manometers and Bourden gauges to measure pressure. |

| C403.2 | CO2. Use flow meters to measure the rate of flow. |

| C403.3 | CO3. Maintain flow through pipes. |

| C403.4 | CO4. Maintain the jet impact on various types of vanes for optimum efficiency. |

| C403.5 | CO5. Maintain hydraulic turbines. |

| C403.6 | CO6. Maintain hydraulic pumps. |

| Course Name: MPR 22446 | |

|---|---|

| C404.1 | Produce jobs using lathe and drilling machines. |

| C404.2 | Produce jobs using Shaping and Slotting operations. |

| C404.3 | Prepare Product using different casting processes |

| C404.4 | Prepare Product using different Forming processes |

| C404.5 | Use Joining Process to Produce Jobs |

| Course Name: EST 22447 | |

|---|---|

| C405.1 | Develop public awareness about the environment. |

| C405.2 | Select alternative energy resources for Engineering practice. |

| C405.3 | Conserve Ecosystem & Biodiversity. |

| C405.4 | Apply techniques to reduce environmental pollution. |

| C405.5 | Manage social issues & Environmental ethics as lifelong learning. |

| Course Name: CAD 22042 | |

|---|---|

| C406.1 | Use file management techniques in CAD software |

| C406.2 | Draw complex 2D geometric figures using CAD software. |

| C406.3 | Modify complex 2D geometric figures using CAD software |

| C406.4 | Use software to dimension and write text on existing 2D geometric entities. |

| C406.5 | Use software to plot existing drawings with desired plot parameters. |

| C406.6 | Create Isometric drawings using CAD software |

| C406.7 | Use layers and blocks to create digital drawings using relevant software. |

| Course Name: FOM 22048 | |

|---|---|

| C407.1 | Identify different instruments, sensors, actuators, microprocessors, software, and mechanical components in mechatronics-based systems |

| C407.2 | Use sensors for different mechatronics applications. |

| C407.3 | Use transducers for different mechatronics-based applications. |

| C407.4 | Use actuators for various mechatronics-based applications. |

| C407.5 | Program PLC for various applications. |

| C407.6 | Use microprocessors and microcontrollers for various mechatronics-based applications. |

| MECHANICAL ENGINEERING PROGRAM |

|---|

| SEMESTER – FIFTH | |

|---|---|

| CO No. | Course Outcomes |

| Course Name: MAN 22509 | |

| C501.1 | Use basic management principles to execute daily activities |

| C501.2 | Use principles of planning and organizing for the accomplishment of tasks. |

| C501.3 | Use principles of directing and controlling for implementing the plans. |

| C501.4 | Apply principles of safety management in all activities |

| C501.5 | Understand various provisions of industrial acts |

| Course Name: PER 22562 | |

|---|---|

| C502.1 | Identify different components of IC engines and their auxiliaries |

| C502.2 | Test the performance of the IC engine |

| C502.3 | Maintain reciprocating air compressor |

| C502.4 | Identify different components of Gas turbine and jet engines |

| C502.5 | Test the performance of refrigeration and air conditioning systems. |

| Course Name: AMP 22563 | |

|---|---|

| C503.1 | Maintain the nonconventional machining process to produce complex and hard-to-machine components. |

| C503.2 | Produce components using the milling machine. |

| C503.3 | Choose the relevant machining process to produce gears. |

| C503.4 | .Maintain CNC machines to produce components effectively. |

| C503.5 | Prepare CNC part programs for simple components. |

| C503.6 | Maintain the functioning of automated equipment. |

| Course Name: EMD 22564 | |

|---|---|

| C504.1 | Select suitable materials for designing machine elements |

| C504.2 | Design joints and levers for various applications |

| C504.3 | Design the power transmission elements like shafts, keys, and couplings |

| C504.4 | Recommend the power screws and suitable fasteners for different applications |

| C504.5 | Choose springs for various applications |

| C504.6 | Select standard components with their specifications from the manufacturers' catalog |

| Course Name: TE/N 22565 | |

|---|---|

| C505.1 | Interpret geometries of various cutting tools |

| C505.2 | Use relevant cutting tool inserts and tool holders for different machining operations |

| C505.3 | Use relevant locating and clamping devices for components |

| C505.4 | Use relevant jigs and fixtures for components and machining operations |

| C505.5 | Use relevant press tool and press tool operation |

| C505.6 | Use the relevant die for bending, Drawing, and forging simple components |

| Course Name: ITR 22049 | |

|---|---|

| C506.1 | To enable students to learn the basic concepts of Project & Production Management of industries. |

| C506.2 | Develop individual confidence to handle various engineering assignments and expose them to acquiring life skills to meet societal challenges. |

| C506.3 | To study the concept of Facility, Location & Layout & implementation/Expertise /domain /Product in their Industrial In-plant training Project work. |

| C506.4 | Enhance communication skills and life-long learning, and acquire technical skills, employability skills, Practical skills, risks in industry, management skills, and other skills that are conducive to professional engagement. |

| C506.5 | .Identify career paths taking into account their strengths and aptitude and Prepare a report about the work experience in the industry |

| Course Name: CPP 22050 | |

|---|---|

| C507.1 | Write the problem/Task Specification in the existing system related to the occupation. |

| C507.2 | Select, Collect, and use the required information/Knowledge to solve the problem to complete the task |

| C507.3 | Logically choose the relevant possible solutions |

| C507.4 | Consider the ethical issues related to the project. |

| C507.5 | Assess the impact of the project on society |

| C507.6 | Prepare project proposal with action plan and time duration scientifically before beginning of the project |

| C507.7 | Communicate effectively and confidently as a member and leader of the team. |

| Course Name: SMA 22053 | |

|---|---|

| C508.1 | Prepare 2D Drawing using a sketcher workbench of any parametric CAD software. |

| C508.2 | Generate 3D Solid models from 2D sketches using the Part workbench of any parametric CAD software. |

| C508.3 | Prepare assembly of part models using the Assembly workbench of any parametric CAD software. |

| C508.4 | Generate orthographic views of 3D solid models/assemblies using a drafting workbench of any parametric CAD software. |

| C508.5 | Plot a drawing for the given part model/assembly. |

| C508.6 | Print components using a 3D Printer/Rapid prototyping machine. |

| MECHANICAL ENGINEERING PROGRAM |

|---|

| SEMESTER – SIXTH | |

|---|---|

| CO No. | Course Outcomes |

| Course Name: ETM 22652 | |

| C601.1 | Identify different New Systems available in Automobile |

| C601.2 | Apply Heat engineering principles in process boilers and waste heat recovery systems used in Process Industry |

| C601.3 | Cite examples of Modern Manufacturing Technology in the industry |

| C601.4 | Use different standards for energy Management and Audit of a given system |

| C601.5 | Select different agricultural equipment for pre and post-harvesting |

| Course Name: IHP 22655 | |

|---|---|

| C602.1 | Identify various components of Hydraulic and pneumatic systems. |

| C602.2 | Select the Pump and Actuator for the given fluid-operated system. |

| C602.3 | Select the Appropriate Control valve for the given fluid-operated system |

| C602.4 | Select the Compressor And Appropriate accessories for the given fluid-operated system |

| C602.5 | Develop different hydraulic circuits for given simple application |

| C602.6 | Develop different pneumatic circuits for given simple application |

| Course Name: AEN 22656 | |

|---|---|

| C603.1 | Prepare vehicle layouts with chassis specifications. |

| C603.2 | Interpret power flow diagrams of transmission systems. |

| C603.3 | Select suitable braking and steering systems for different applications. |

| C603.4 | Select a suspension system for different applications. |

| C603.5 | Prepare simple electrical-electronic circuits for automobile systems. |

| C603.6 | Select service tools for relevant service operations in automobile shops. |

| Course Name: IEQ 22657 | |

|---|---|

| C604.1 | Apply work study techniques to optimize manufacturing processes. |

| C604.2 | Prepare the detailed sequence of operations for manufacturing of components. |

| C604.3 | Apply Ergonomic principles for designing simple mechanical components. |

| C604.4 | Interpret the data obtained from the different quality control processes |

| C604.5 | Interpret control charts for variable and attribute data. |

| Course Name: RAC 22660 | |

|---|---|

| C605.1 | Use refrigeration systems for a given application |

| C605.2 | Use relevant refrigerants for different applications. |

| C605.3 | Select different refrigeration components for a given refrigeration system. |

| C605.4 | Select different air-conditioning components for a given air-conditioning system. |

| C605.5 | Determine cooling loads for Air-conditioning systems. |

| C605.6 | Select relevant tools for maintaining air conditioning systems |

| Course Name: EDE 22032 | |

|---|---|

| C606.1 | Identify your entrepreneurial traits. |

| C606.2 | Identify the business opportunities that suit you. |

| C606.3 | Use the support system to zero down on your business idea. |

| C606.4 | Develop a comprehensive business plan |

| C606.5 | Prepare a plan to manage the enterprise effectively. |

| Course Name: CPE 22060 | |

|---|---|

| C607.1 | Implement the planned activity individually or as a team |

| C607.2 | Select, collect, and use the required information/knowledge to solve the identified problem |

| C607.3 | Make appropriate decisions based on collected and analyzed information. |

| C607.4 | Ensure quality in a product. |

| C607.5 | Incorporate energy and environment conservation principles |

| C607.6 | Consider the ethical issues related to the project (if any). |

| C607.7 | Assess the impact of the project on society. |

| C607.8 | Communicate effectively & confidently as a member and leader of a team. |

| C607.9 | Prepare project report after performing due plagiarism check using appropriate tools. |